|

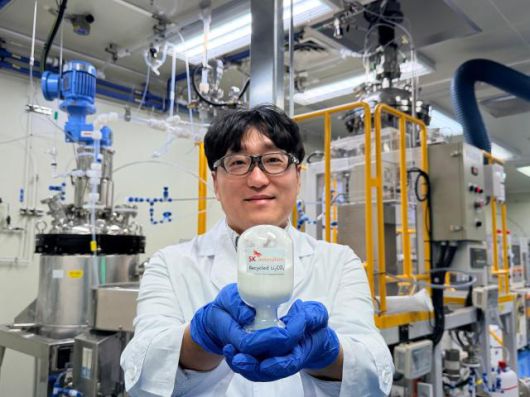

[사진=SK이노베이션] |

<이미지를 클릭하시면 크게 보실 수 있습니다> |

SEOUL, December 05 (AJP) - South Korea's SK Innovation said Friday its lithium iron phosphate (LFP) battery recycling technology has been published in the international journal Separation and Purification Technology.

The company said conventional recycling processes for LFP batteries have struggled with environmental and cost burdens, including byproduct treatment and wastewater generation. Its newly developed method uses only water, carbon dioxide and hydrogen peroxide to selectively extract high-purity lithium carbonate, eliminating the need for harsher chemicals.

SK Innovation described the process as an eco-friendly solution that overcomes long-standing challenges in LFP recycling. The company expects the technology to support the broader battery ecosystem by reducing environmental impact while enabling more efficient resource recovery.

SK On, SK Innovation’s battery-making unit, is preparing to manufacture pouch-type LFP cells for EVs and energy storage system applications. As LFP adoption accelerates, industry officials say securing stable recycling channels — particularly for lithium recovery — has become a critical element of supply-chain resilience and cost competitiveness.

“This achievement surpasses the limitations of existing battery recycling methods and is a key technology for sustainable battery market growth,” said Kim Pil-seok, head of SK Innovation’s Environmental Science and Technology Institute.

“By stably recovering high-purity lithium carbonate, we aim to mitigate lithium supply risks and expand collaboration with domestic and international battery makers and recyclers.”

* This article, published by Aju Business Daily, was translated by AI and edited by AJP.

Lee Nak-yeong 기자 nakk@ajunews.com

- Copyright ⓒ [아주경제 ajunews.com] 무단전재 배포금지 -

이 기사의 카테고리는 언론사의 분류를 따릅니다.

기사가 속한 카테고리는 언론사가 분류합니다.

언론사는 한 기사를 두 개 이상의 카테고리로 분류할 수 있습니다.

언론사는 한 기사를 두 개 이상의 카테고리로 분류할 수 있습니다.